The MTI Difference

Why MTI

Our simple, modern development process sets us apart from traditional, overwhelming processes. We help you find and navigate the best path to successfully implement friction welding into your part design and production. We stand ready to support you on your timeframe and wherever you may be in your journey to friction welding. Working with MTI should be an easy and rewarding collaboration from start to finish. We’ll build a machine for you that makes the part, we’ll make the part for you, or we’ll help you make a part better.

Set Expectations

- Process definement Research and development

- Conceptual design engineering

Define Ownership

- Metallurgical evaluations

- Quality verification

- Material procurement

- Cost confirmation

Commit Resources

- Traditional machine build

- Manufacturing services

Measure & Review

- Worldwide service and support

- Preventative maintenance

- Parts assurance

1. Pre-Production: Set Expectations

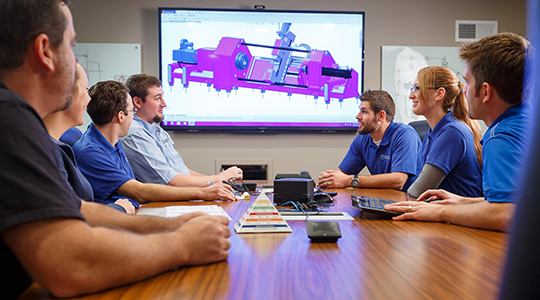

We kick off the process by hosting you and your team for a site visit to our manufacturing facility. Or better yet, we will come to you. This helps both our teams develop a collaborative working relationship in conceptualizing the best friction welding solution for your industry application.

Process Definement

We’ll listen, discuss, and review your complete pre- and post-weld processes and part functionality to fully understand your application and then show you how our multifaceted approach:

- Expanding conventional thinking about manufacturing, welding, and joining

- Reducing cycle time

- Increasing throughput

Research & Development

We can help you increase the performance, capabilities, or range of your product and help reduce costs by exploring:

- Process improvements

- New designs

- New applications

Conceptual Design Engineering

We tailor solutions for your applications and manufacturing processes, for example:

- Custom tooling and parts

- Components with difficult welding conditions previously considered unachievable

- Integrated automation so you have a complete welding system, not just a machine

2. Sample Manufacturing: Define Ownership

Metallurgical Evaluations

Quality Verification

Material Procurement

Cost Confirmation

Ready to learn more?

3. Production: Commit Resources

Time to let the fun begin! Now we can determine which route we should go to produce the best results for you – traditional friction welding machine build, parts production from our Manufacturing Services group, or a strategy that includes both. Many customers start with a development program, then utilize our Manufacturing Services group for parts production while their machine is built. Others leverage our Manufacturing Services group to support their production spikes that exceed their machine capacity.

Traditional Friction Welding Machine Build

Helping companies worldwide solve their manufacturing problems is why we design, manufacture, install, and service a complete line of integrated friction welding machines. MTI has designed, built, and supported over 800 friction welding machine solutions worldwide. Read our customer stories.

Manufacturing Services

Not enough volume to justify the cost of building your own machine? Looking to support your production demand spikes or develop the next generation of friction welding parts without crimping your current machine production? We serve as your single-source solution, developing and producing your parts to save you time and money, all while mitigating risk to your parts program.

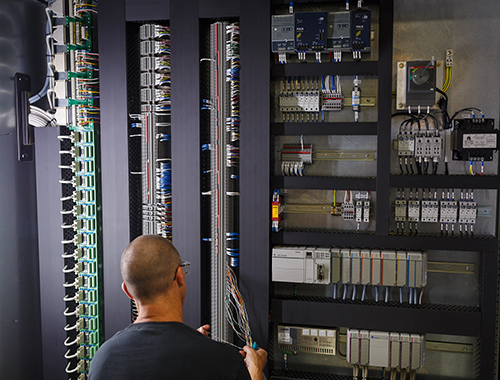

Aftermarket Service & Parts

Looking for machine service or spare parts? Our expert technicians can recommend suitable maintenance packages or schedule an on-site visit for a machine check-up. Keep your machine running at its best with MTI’s expert service.

4. After Sales Support: Measure and Review

To help you care for your investment, we provide you with a dedicated Customer Service team, an extensive warranty, preventative maintenance packages, parts assurance, and much more.

Want to see how MTI can make a difference in your next project?