In the world of Aerospace and advanced engineering, titanium forgings have long been hailed as critical, unique materials for their lightweight yet high strength properties. However, a recent and developing disruption to the existing supply chain may threaten the availability of these critical components.

Amidst this challenging scenario, a promising solution emerges – Linear friction welding, a cutting-edge technique that has the potential to mitigate the crisis and revolutionize the manufacturing of titanium forgings.

The Challenge

As a critical and highly demanded material, supply chain issues cause disruptions for the companies that depend on it. Given the sometimes complex geometry and critical nature of the components manufactured from the forgings, the tooling and machines required to provide an alternative solution to component supply are not easily replaced. That brings us to the current challenge. Russia is a top supplier in the titanium market, accounting for nearly 20% of the global supply and 45% of titanium Aerospace components.

With international sanctions being imposed against Russia (and predicted to increase), it’s essential to consider alternative ways of manufacturing titanium forgings that are cost effective and environmentally conscious.

Titanium Forgings

So, why are titanium forgings so unique?

Titanium forgings refers to Titanium that has undergone a forging process where the metal is hot forged into the required geometry according to the desired application. By undergoing a forging process, the titanium gets enhanced strength, improved material integrity, and a longer useful life with minimal maintenance needed because the grain direction is manipulated in accordance to the load path within the component during its service life. Besides enhanced strength, titanium is also forged because the price per pound of raw titanium is high, and forgings are designed to minimize the amount of expensive material that needs to be removed.

And for the Aerospace industry where many airframe components are manufactured from titanium forgings since the end product typically weighs between 150-220 tons, titanium is a critical component when trying to trim weight without compromising safety of mission critical components.

Forging A Solution: Linear Friction Welding

Like all friction welding processes, Linear friction welding is a forging technique that generates heat from relative motion and axial force to create a solid-state weld. Linear friction welding applies an oscillatory motion while the components are in contact to generate heat which allows any geometry to be joined. Once the oscillatory motion between the components has plasticized the weld interface, the bond is consolidated by rapidly stopping oscillation and forging the components together creating a solid-state bond.

So, how can Linear friction welding be used to manufacture titanium forgings?

One of the most unique benefits that Linear friction welding offers is near-net shape joining, also known as close contour. Near-net shape manufacturing is the process of joining several smaller parts to form a larger part. This enables 3 dimensional tailored blanks with virtually any geometry to be produced on a single machine. Using the appropriate tooling, near-net shapes can be built from individual stock sections or smaller forgings, allowing the finalized welded part to be very close to the end product’s geometry. You may recall near-net shape manufacturing for blisks in the Aerospace industry.

But, did you know that near-net shape manufacturing is especially advantageous for titanium and titanium alloys? That’s because titanium is an expensive material, and close contouring provides production flexibility and reduces machining time and production costs while wasting less material. In other words, Linear friction welding can reduce Aerospace companies’ buy-to-fly ratio by up to 90% when compared to billet machining and around 50% when compared to forging with near-net shape manufacturing of titanium. In addition to the material cost and machining time savings, near-net shapes manufactured from prismatic stock material provide consistent clamping locations and eliminate the need for a separate pre-machining step for clamping faces during production.

Another unique advantage of Linear friction welding is the ability to manipulate the grain structure of the material, in this case titanium. Linear friction welding has the ability to align the grain structure of the subsections within the tailored blank in accordance with the load path of the part. This is especially beneficial as favorably manipulating the grain structure increases the performance of the titanium in comparison to billet machining, making the Linear friction welded component performance similar to that of forged structures all while using less energy, less material, and less machining time than traditional forging methods.

The Process

MTI has developed a streamlined production process using titanium subsections to produce full-scale, near-net shapes. Take a look:

1. Nesting of titanium blanks from plate – The process starts with a titanium plate. The components needed to construct the near-net shapes will be orientated according to the rolling direction of the material and the most efficient extraction layout. The components will then undergo water jet cutting.

2. Weld subsections together – This is where Linear friction welding comes in. In most cases, with the correct tooling, the components can be welded directly from the water jet cutting machine. Depending on the geometry of the manufactured part, some pre-weld preparation may be required. Linear friction welding can then be performed in sequence to produce near-net shapes from the titanium. During construction, complex geometries or critical safety components might need to undergo non-destructive testing. However, this can be done using automation systems away from the friction welding machine, if necessary.

3. Heat treatment – MTI has worked closely with multiple manufacturers to define an appropriate heat treatment and stress relieving process that compliments the Linear friction welding process. Heat treating helps to avoid the formation of cracks in the material and can further improve fatigue resistance.

4. Final machining – Once Linear friction welding is completed, final machining must be done to the near-net shape parts to complete the component’s final form.

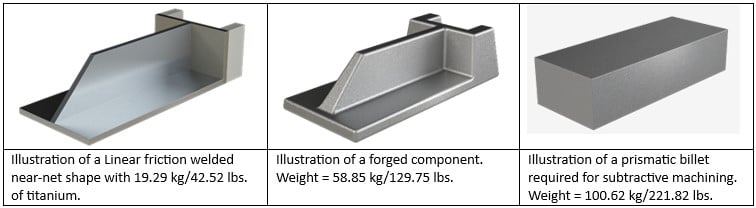

This illustration evaluates the differences in material required to produce a pre-machined near-net shape when using LFW (Linear Friction Welding), forgings, and a prismatic billet. In this generic comparison, an LFW blank and a forging would yield a 67% reduction in material in comparison to a forging, and an 80% reduction in comparison to a prismatic billet. While these figures are hypothetical, they are indicative of actual values that have been defined through detailed product assessments.

And, getting started with friction welding is easier than you may think! At MTI, we have teams dedicated to helping you from the creation of your part drawings to the manufacturing of production-ready components, all included in our comprehensive Weld Development program.

Getting Started

By now, you should have a better understanding of what Linear friction welding can do for you. If you still have questions, or if you’re ready to talk shop, contact Simon Jones, MTI’s Director of Aerospace, to get a conversation started!

LinkedIn: https://www.linkedin.com/company/manufacturing-technology-inc

YouTube: https://www.youtube.com/c/ManufacturingTechnologyIncMTIJoiningSolutions/videos