It’s a scenario you’ve likely encountered at least once.

You have two metals you want to join, but you’re not sure which welding technology is the best fit for your application.

There are dozens of viable welding options to explore, but in our world of solid-state joining, we most frequently receive questions about the similarities between our processes and fusion welding.

We will use this article to compare Low Force Friction Welding to laser welding.

We frequently talk about the differences between traditional friction welding and Low Force Friction Welding. But with the added benefits from Low Force, it’s now reasonable to stack it up against a fusion process such as laser welding to examine the differences.

WHAT IS LOW FORCE FRICTION WELDING?

Low Force Friction Welding has all the value-added benefits of traditional friction welding, but those advantages are multiplied.

Low Force Friction Welding is a relatively new technology and uses an external energy source to raise the interface temperature of the parts being welded. This reduces the process forces required to make a solid-state weld compared to traditional friction welding.

Low Force Friction Welding can provide faster cycle times, reduced flash, smaller machine size and can accommodate a wider range of parts for all industries.

WHAT IS LASER WELDING?

Laser welding has been around since at least the 1970s and is often used in the automotive, medical and consumer electronics industries.

In this technology, laser light is an energy source for the melting of materials to accomplish a weld. Though unlike TIG and MIG welding, the laser light can be focused to very small spot sizes with high power density. That benefit alone offers higher speed and deeper weld penetration compared to other fusion processes.

Laser welding is often touted for its consistent, high-quality welds. It has long been an ideal choice for medical, consumer products and automotive applications. It’s also a top choice for jewelry welding because of its ability to join a wide range of precious metals.

EXAMINING THE TWO TECHNOLOGIES

Laser welding and Low Force Friction Welding share a list of benefits. Those advantages make both laser welding and Low Force Friction Welding highly effective technologies, and in many cases, more effective than TIG and MIG welding.

Here are a few benefits you can find in both Low Force Friction Welding and laser welding:

Repeatability: Both friction welding and Low Force Friction welding are highly repeatable processes thanks to the ability to automate. Laser welding is also a highly autonomous process, again giving these two technologies a significant advantage over MIG and TIG welding in terms of efficiency.

Narrow Heat Affected Zone: With an optimized form of Low Force Friction Welding and a high-gradient pre-heat, a very narrow Heat Affected Zone (HAZ) can be accomplished with our process. Similarly, the high speeds of laser welding reduce the diffusion of heat into materials. This also makes for a narrow HAZ.

Precision: Because of the radial positioning control techniques practiced in both traditional and Low Force Friction Welding, our process is precise with each weld. The technology behind laser welding also allows this joining technology to offer a high level of accuracy and control.

Raw Material Cost Savings: Unlike MIG and TIG welding, neither Low Force Friction Welding or laser welding use filler material to complete a weld. This also further enhances each technology’s capability to produce lightweight parts.

A FOUNDATIONAL DIFFERENCE

While there are many materials and geometries that could be joined with both Low Force Friction Welding and laser welding, it all comes down to the advantages you’re hoping to gain from the process.

Low Force Friction Welding is a solid-state process – that means joining occurs below the melting temperature of the two parts being joined, making the weld superior to those created in fusion processes, such as laser welding.

With Low Force Friction Welding, the materials are taken to the point where they will plasticize without melting. The result is a weld that is free of solidification defects and of mechanical properties similar to those of the parent metals.

NEED FOR SPEED

In terms of cycle times, Low Force Friction Welding often exceeds the capabilities of laser welding.

Here’s an example:

For a round application from the automotive industry, laser welding joined the part in approximately 1 minute and 20 seconds.

Using the same part with Low Force Friction Welding, the weld was complete in just 15 seconds, an 80 percent reduction in overall cycle time.

So, what makes Low Force so much faster?

With laser welding, the laser welds one section (or spot) at a time. Traditional friction welding joins the whole weld area simultaneously. With Low Force, it’s even quicker because instant pre-heat is added to the process, making it more efficient than both traditional friction welding and laser welding in this case.

FLASH: NOW YOU SEE IT, NOW YOU DON’T

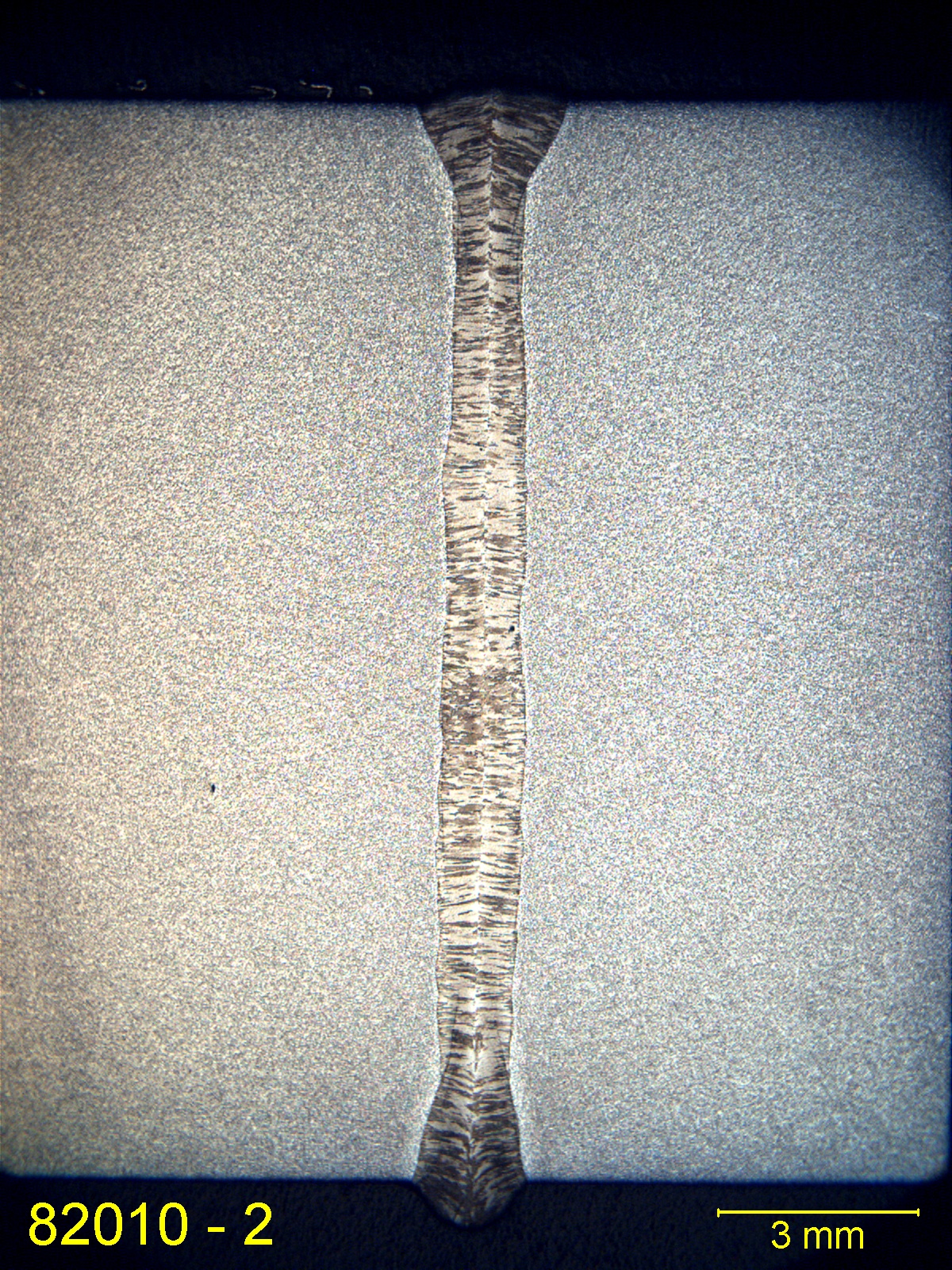

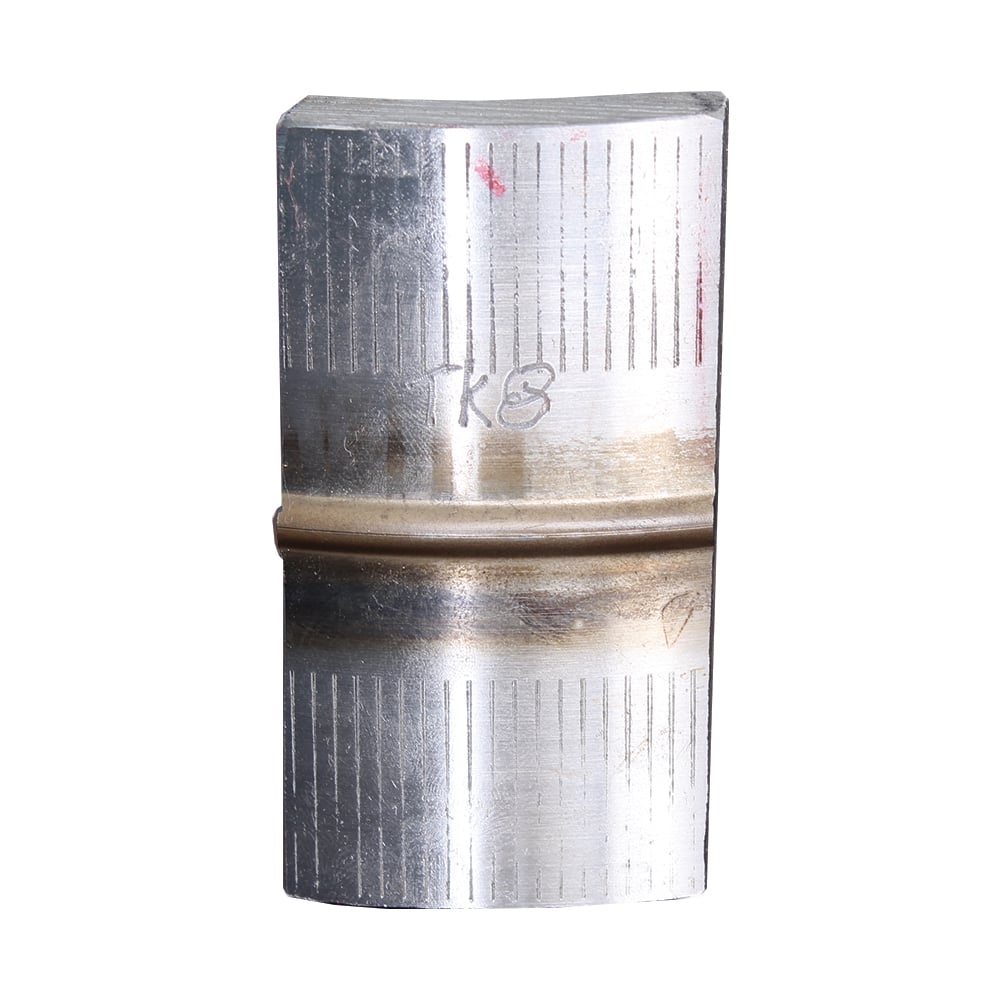

For applications that require flash removal, laser welding has historically edged out traditional friction welding due to the flash curl on the OD and ID. But because Low Force Friction Welding produces minimal or sometimes nonexistent flash, Low Force Friction Welding can now be a viable solution for applications that need a smooth surface at the weld line for different types of materials.

Laser weld ©EWI. Used with permission. Flash formation on Low Force weld.

BIMETALLIC JOINING

Both traditional and Low Force Friction Welding allow for the joining of dissimilar metals – a benefit that again sets solid-state welding apart from laser welding.

In laser welding, bimetallic combinations often display low plastic deformability, which can cause materials at the weld line to be brittle.

While laser welding typically joins materials made of steel, stainless steel and aluminum, Low Force Friction Welding offers more material flexibility.

MTI has successfully joined dozens of material combinations such as Copper to Aluminum, Steel to Inconel and many more.

Plus, with the added flexibility of Low Force Friction Welding, we can now join more unique geometries and a wider size range of parts.

THE TAKEAWAY

While laser welding is certainly a proven process and, in some cases, may be a better choice than traditional friction welding, the value-added benefits of Low Force Friction Welding could make our newest joining technology an attractive solution. Low Force can accommodate more complex parts, thinner walls, and unique geometries that cannot handle the high process forces of traditional friction welding.

Even with the value-added benefits of Low Force Friction Welding, there are a few areas where laser welding would be preferred, such as extremely small parts like jewelry and highly sterile medical applications. However, while laser welding is good for these smaller welds, it does present issues when scaling to larger welds.

If you want to explore the possibilities of Low Force Friction Welding with smaller parts, our new Microwelder offers smaller-than-ever solid-state joining for all industries.

This small-scale Low Force Friction Welding machine is ready for your development work today.

LET’S CONNECT

Ready to learn all of the other benefits that Low Force Friction Welding has to offer?

Contact us to start the conversation.