When you think of friction welding, rotary, linear and friction stir welding are the first to come up in a Google search.

However, there is another more unique form of friction welding that is specifically designed to help aerospace companies save on Maintenance Repair and Operations (MRO).

It’s called plug welding.

This blog describes the technology behind plug welding and how friction welding keeps aging engine programs airborne.

INTRODUCTION TO PLUG WELDING

Plug welding repairs damage caused from corrosion and vibration, concentrating on aerospace components, such as fan and exit cases. Our process allows aerospace companies to see beyond traditional bushing repair. Plug welding salvages fan cases by addressing each individual damage location, rather than scrapping entire assemblies.

IDENTIFYING THE PROBLEM

After repeated flights, the fastener locations on fan and exit cases enlarge beyond their original design specifications. This problem can be attributed to oxidation caused by saltwater, especially for planes that routinely take off and land from coastal locations.

Airlines traditionally perform temporary repairs, which compounds the problem. Bushings are installed, the corrosion and vibration continues, and the process is repeated until the enlarged fastener location creates a structural concern. At this point the case is scrapped, and hopefully replacement components can still be procured.

HOW PLUG WELDING CAN HELP

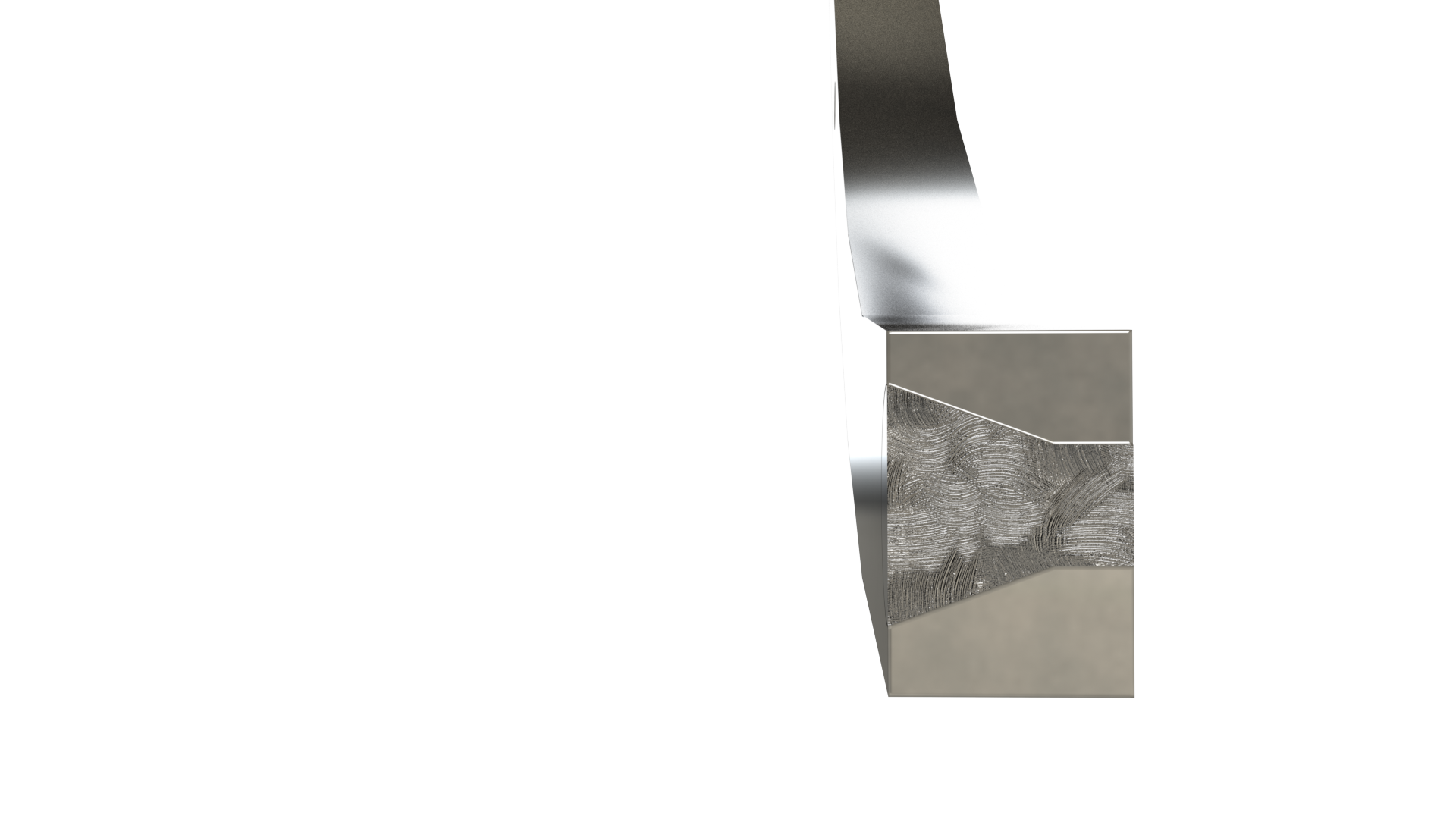

Plug welding is a multi-step process that ultimately repairs damaged holes to near-parent material properties. It also involves machining the component to its original configuration.

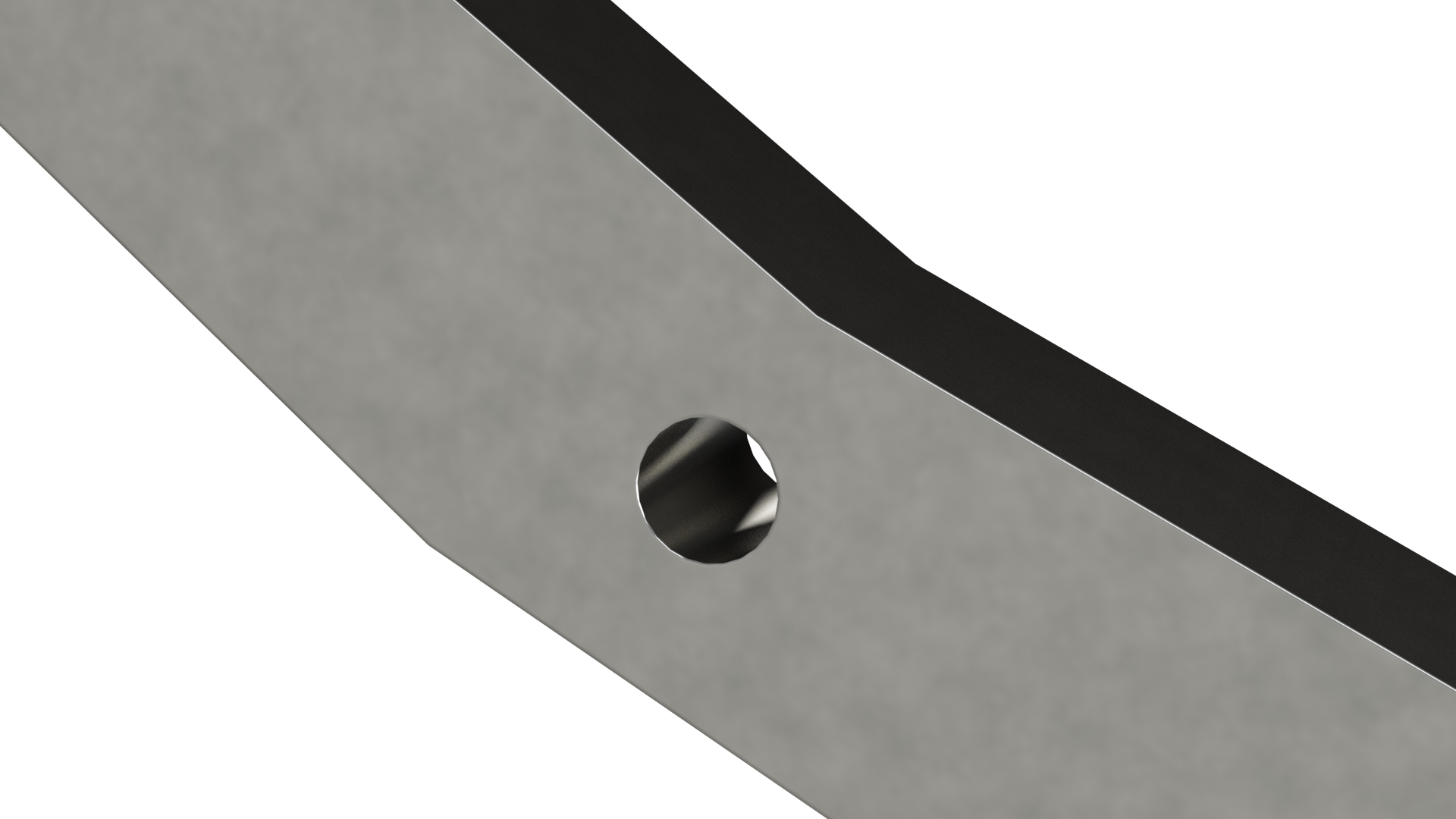

STEP ONE – PREPARING THE HOLE

Before the plug welding process can begin, MTI prepares the damaged hole for repair by drilling the existing hole on-center to create a clean hole of exact diameter.

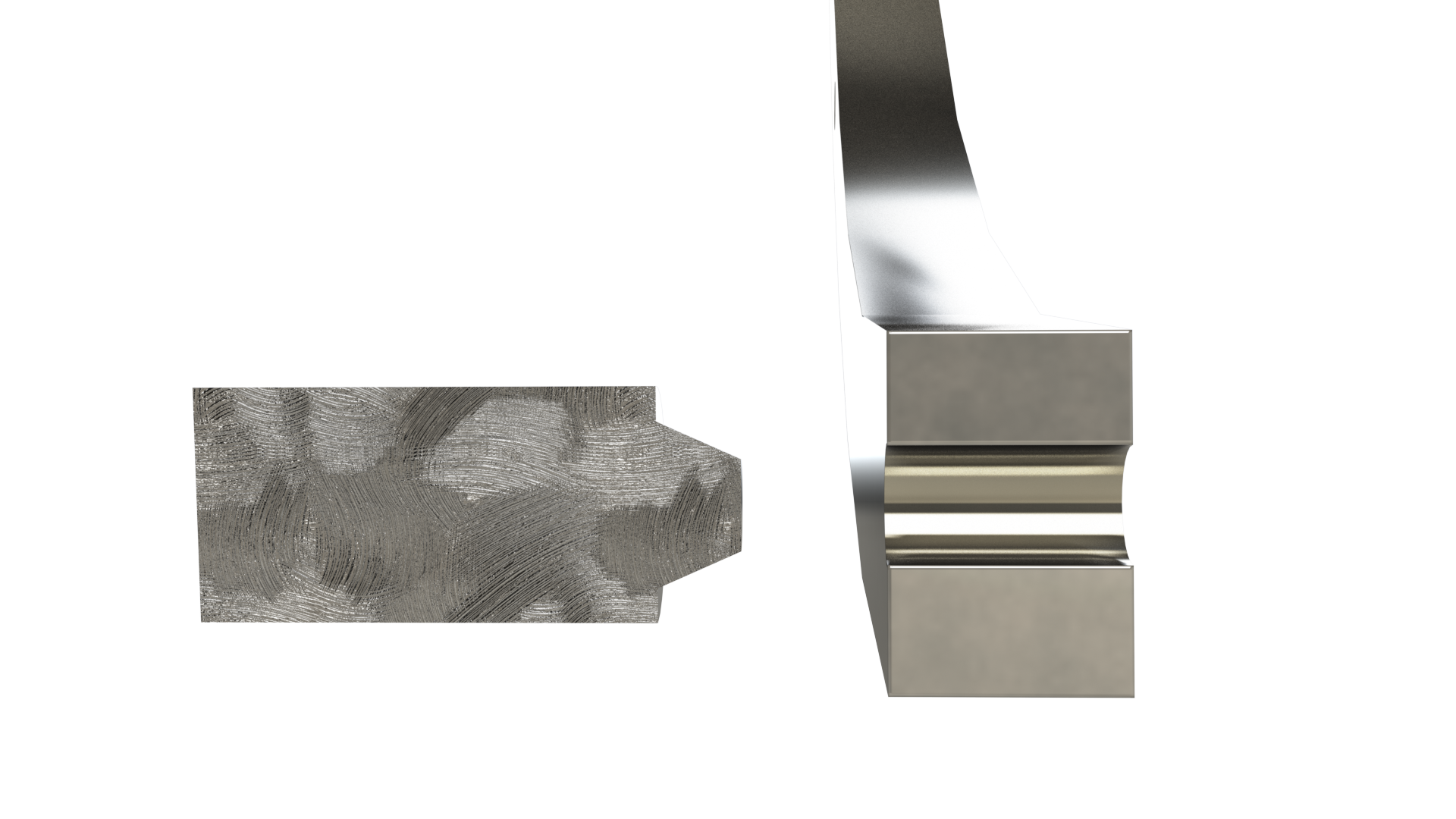

STEP TWO – BEGINNING THE FRICTION WELDING PROCESS

Utilizing an engineered plug tapered-specific for each diameter, MTI solid-state friction welds a new material into the hole.

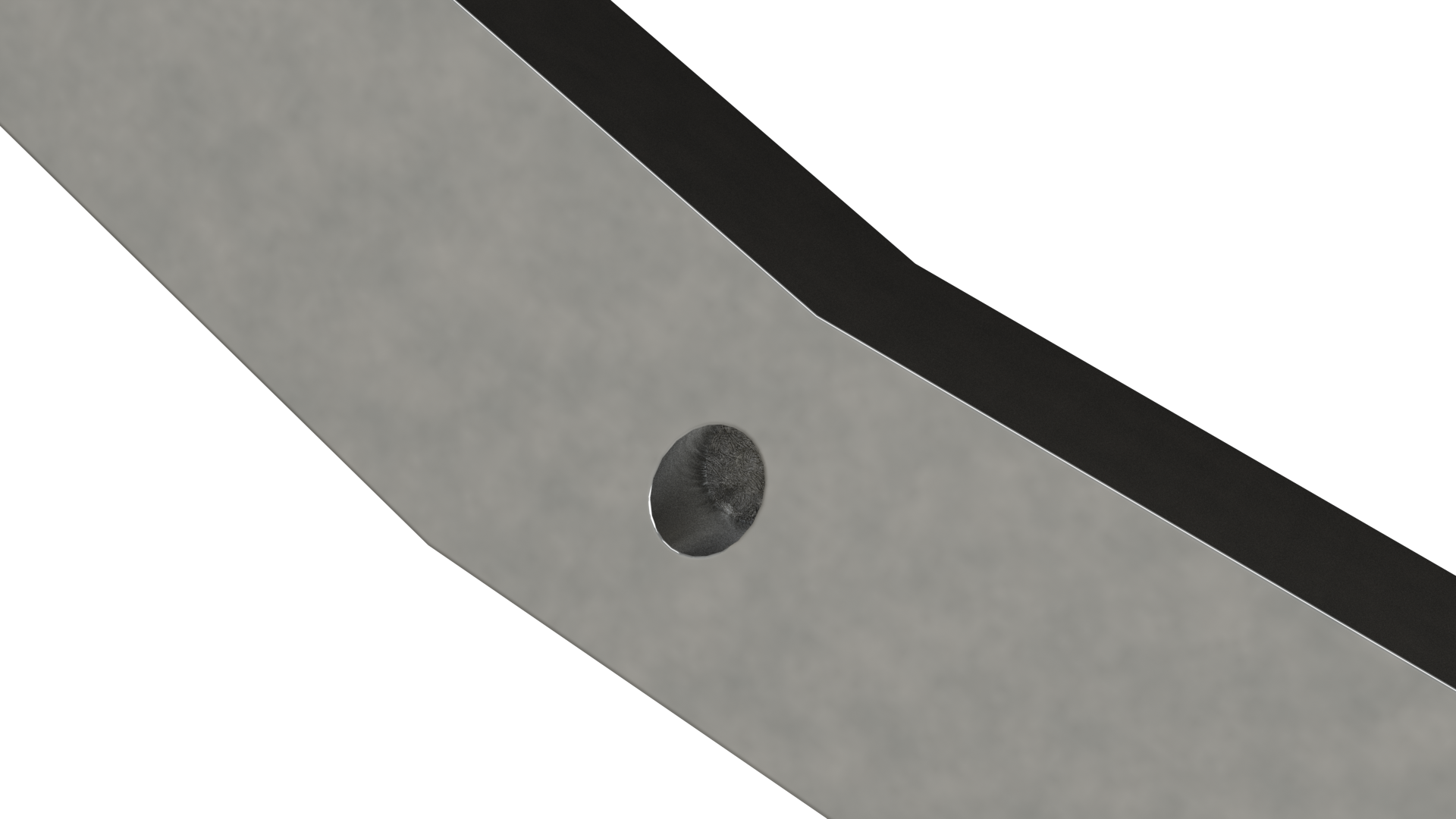

STEP THREE – REMOVING EXCESS MATERIAL

After the new material is in the hole, we machine the excess plug material flush to the original flange surface.

STEP FOUR – PREPARING THE HOLE FOR NEW USE

The repaired hole now contains near-parent material properties and is ready to be drilled on-center.

THE RESULT

Plug welding significantly reduces MRO costs by repairing each hole to like-new condition. Our process ensures timely service, extends the useful life of aerospace components and ultimately improves the efficiency of airlines.

Now that you understand how plug welding works, let’s talk about whether it can help improve your processes and save MRO costs for your company.

Contact us to start the conversation.